Tech Talks: Previews for Upcoming Videos

box build, pcb assembly, pcba, tech talks, videos, webinars, wire harness At PGF Technology Group, our commitment to knowledge sharing extends beyond our cutting-edge custom manufacturing of printed circuit boards (PCBs), cables, wire harnesses, and...Read More

Navigating Custom PCBA FAQs: A Comprehensive Guide

Automated Optical Inspection (AOI), electronic assembly, pcb assembly, pcba, printed circuit board assembly, SMT As the technological landscape continues to evolve, custom Printed Circuit Board Assemblies (PCBAs) have become integral components in the development of cutting-edge electronic devices....Read More

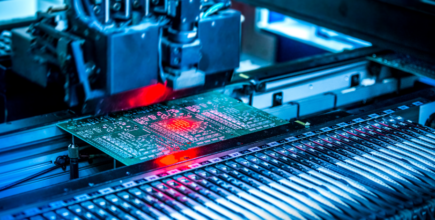

Behind the Scenes: The Making of Custom PCBAs

Automated Optical Inspection (AOI), electronic assembly, flexible pcbas, pcb assembly, pcba, printed circuit board assembly, quality control, SMT Precision and innovation go hand in hand. At PGF Technology Group, a trusted custom manufacturer specializing in printed circuit boards (PCBs), cables, wire harnesses,...Read More

Re-introducing PCBA: Redefining Compact with Impact

electronic assembly, flexible PCBs, iot integration, pcb assembly, pcba, printed circuit board assembly, rigid-flex pcbs, SMT In the fast-paced world of electronics, where innovation is the driving force, Printed Circuit Board Assemblies (PCBAs) play a pivotal role. At PGF Technology...Read More

Enhancing Connectivity: The Role of 5G in Electronics

communication systems, electronic assembly, industrial automation, iot revolution, pcb assembly, pcba, printed circuit board assembly, SMT In the ever-evolving landscape of electronics, connectivity is the heartbeat that powers innovation. As we usher in a new era, 5G technology is emerging...Read More

The Rise of Sustainable Electronics Manufacturing

cable assembly, eco-friendly, energy-efficient, pcb assembly, printed circuit board assembly, recyclability, reduce waste, sustainability, wire harness assembly When environmental sustainability is a global priority, industries are undergoing a transformative shift towards eco-friendly practices, and the electronics manufacturing sector is no exception....Read More

Innovations in PCB Design: What to Watch For

flexible PCBs, high-density interconnects, iot integration, miniaturization, pcb assembly, pcba, printed circuit board assembly, rigid-flex pcbs, smart devices The landscape of electronics is continually evolving, and at the heart of this evolution lies the printed circuit board (PCB). As we delve into...Read More

Tech Trends Recap 2023: A Year of Innovation with PGF Technology Group

enhanced box builds, iot integration, pcb assembly, pcba, printed circuit board assembly, supply chain, sustainable electronics As the calendar turns its final page in 2023, PGF Technology Group takes a moment to reflect on the whirlwind of tech trends that...Read More