Leader In Electronics Manufacturing

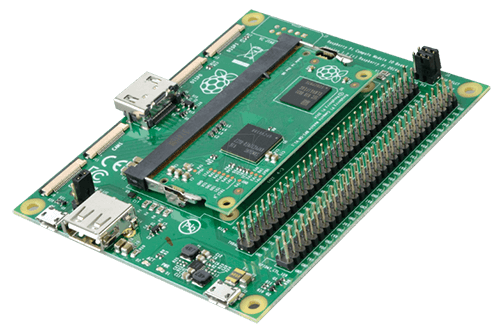

PGF Technology has been a leader in electronics manufacturing for over five decades, specializing in high-precision components like stacked PCB assemblies. Whether we’re producing PCBs for military operations or aerospace applications, our clients can always expect quality, reliability, and efficiency.