When it comes to crafting precision in custom electronic assemblies, every detail matters. At PGF Technology Group, our commitment to excellence extends to the heart of wire harness manufacturing – the Crimp Center. In this blog post, let’s unravel the intricacies of wire stripping, exploring the significance of the Crimp Center in ensuring reliable connections, seamless functionality, and the highest standards in electronic manufacturing.

The Crimp Center: Where Precision Meets Performance

The Crimp Center at PGF is a hub of precision, meticulously designed to handle the intricacies of wire stripping with utmost accuracy. This advanced piece of machinery plays a crucial role in the wire harness manufacturing process, ensuring that each wire is prepared to meet the exacting standards required for optimal performance.

Key Components of the Crimp Center:

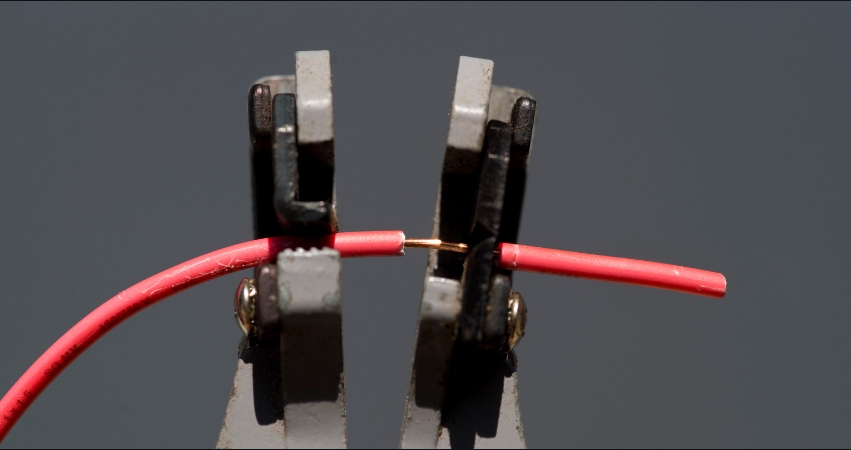

**1. Blades and Cutting Mechanism: Precision begins with the blades. The Crimp Center is equipped with cutting-edge blades that delicately strip away the insulation from wires. This process is essential for creating clean, exposed wire ends that facilitate secure connections.

**2. Adjustable Parameters: Every wire harness is unique, and the Crimp Center’s versatility lies in its adjustable parameters. From wire gauge to insulation thickness, the Crimp Center at PGF can be fine-tuned to meet the specific requirements of each project.

**3. Quality Control Mechanisms: PGF takes pride in ensuring that every wire stripped by the Crimp Center undergoes rigorous quality control. Automated checks and inspections guarantee that only wires meeting the highest standards proceed to the next stages of assembly.

The Importance of Precise Wire Stripping:

**1. Ensures Optimal Connectivity: Reliable connectivity is the backbone of electronic systems. Precise wire stripping is crucial for creating clean and exposed wire ends that form secure connections, minimizing the risk of signal interference or electrical issues.

**2. Facilitates Smooth Assembly: The Crimp Center’s role goes beyond just wire stripping; it paves the way for smooth assembly processes. Wires that have undergone precise stripping are easier to handle and integrate seamlessly into the overall electronic assembly.

**3. Enhances Long-Term Reliability: In the world of electronic manufacturing, longevity is key. The Crimp Center’s precision ensures that wire connections are not just functional today but remain reliable over the long term, contributing to the durability of the final electronic product.

Why Choose PGF for Wire Harness Manufacturing?

**1. State-of-the-Art Facilities: PGF Technology Group invests in state-of-the-art facilities, and the Crimp Center is no exception. Our machinery is equipped with the latest advancements in technology to deliver precision and performance.

**2. Skilled Technicians: The Crimp Center may be a sophisticated machine, but it takes skilled technicians to harness its full potential. PGF’s team of experts is well-versed in the intricacies of wire harness manufacturing, ensuring that every wire meets the highest standards.

Conclusion: Elevating Wire Stripping to an Art Form

At PGF Technology Group, wire stripping is not just a process; it’s an art form elevated by the precision of the Crimp Center. As we continue to push the boundaries of excellence in custom electronic assemblies, our commitment to perfection remains unwavering.

Ready to Experience Precision in Wire Harness Manufacturing?

Contact PGF Technology Group today and leverage our expertise in wire stripping for your next custom electronic assembly project. Let’s craft connections that stand the test of time.